As a production press runs, the temperature of the press increases through friction. We can simulate the temperatures of a production press using our compaction simulator. Materials with a low melting point are most at risk.

Why do we need Temperature Sensitivity testing?

The scale-up of tablet manufacturing can be difficult. The issues seen are the effects of compression speed and the build-up of heat due to the length of the compaction, as it cannot be determined on a smaller scale.

During the compaction of powder, temperatures rise in the compressed powder which can affect the physiochemical properties.

A formulation may be performing well, and after several hours, problems start to occur with material sticking to the punches. The sticking could be temperature related. The heat that is generated can be caused by friction which in turn causes and increase in temperature.

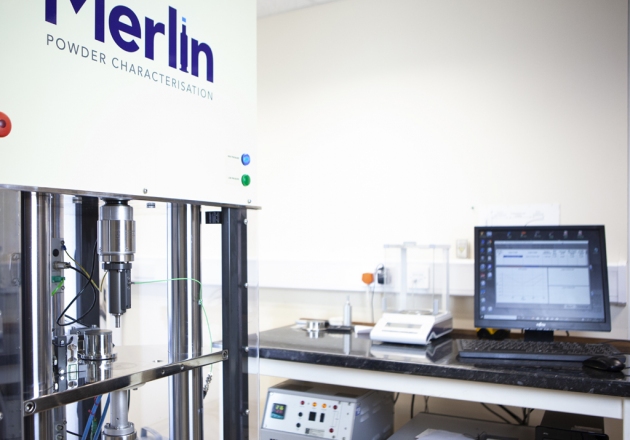

High Temperature Simulation

Merlin has a temperature controlled die that can simulate the higher operating temperatures which occur on a real full scale production press (-10°C up to 70°C) to assess the impact of temperature on the behaviour of the formulation during compaction and ejection.

The effect of scale up temperatures can be predicted using small scale tests on a few grams of material. Knowing what to expect on scale up will avoid any nasty surprises.

During compression, heat is generated through friction, the deformation and fragmentation of materials and change over the length of time of operation.

Have you also considered ejection force measurement and punch adhesion to see whether temperature affects sticking during compression?

Ask Us For A Consultation Call

Or you can call us on +44(0)1384 900 265