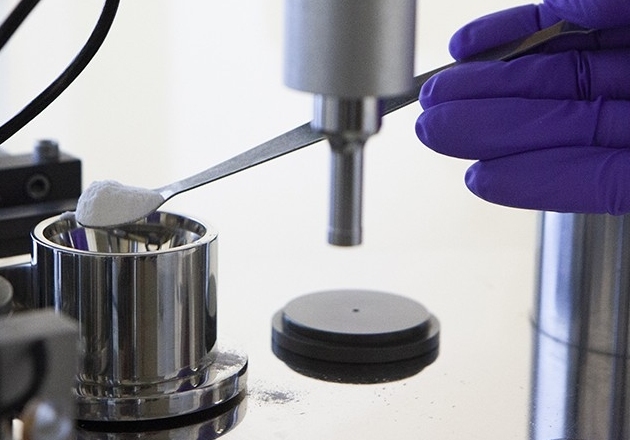

The first part of the investigation was to assess the compactability of the blends which were used to make the roller compaction granules. The API and excipients were blended together using a Turbula T2 blender and compacted using a hydraulic compaction simulator. A roller compaction simulation profile was used to densify the materials to simulate the effects of roller compaction.

We use a sine wave profile to simulate tablet press compaction to assess how the granules would perform in production. The simulated ribbons were compacted and milled. The granules were then compressed over a range of forces to construct pressure/tensile strength plots to understand how solid fraction affects the compressibility of the granules.

The chosen roller compaction process was used to create a new set of compacts to be turned into granules. The granules were blended with extra granular excipients to form a final tablet blend. The performance of the final formulation was assessed and showed the formulation had good strength to make tablets. The results were reported and sent to the client.