Merlin has been working with a US-based pharmaceutical company. Our client has been having sticking issues during production. Tablet adhesion can appear unexpectedly at a late stage and can be difficult to solve. We can run tests using specialist equipment to measure the adhesion risk and troubleshoot any potential issues.

What Did We Do?

Merlin looked at the Ejection Force Measurement which is the force measured on the lower punch as the tablet is pushed out of the die at the end of the tablet compression process. This measurement can be used to determine if the optimum amount of lubricant has been added to the formulation.

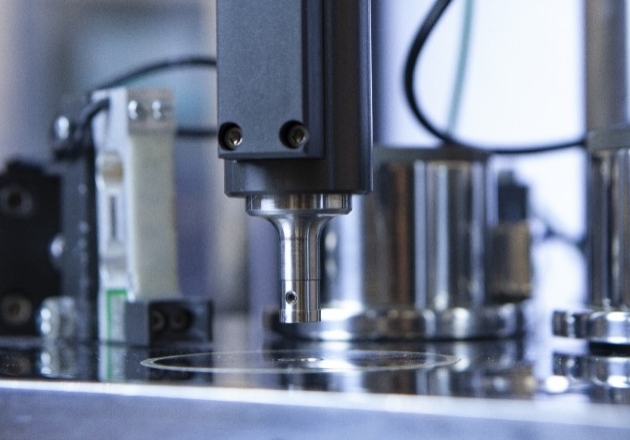

We used a specially designed instrumented adhesion punch to measure the force between the upper punch face and the upper surface of the compact. We also checked the suitability of punch coating solutions on a formulation. After compression, the punch tip remains adhered to sticky surfaces and, as the punch pulls away, a force is measured by the sensor. The greater the pull required to unstick the tablet from the surface, the greater the measurement.

Our Case Study Highlights:

- We looked at the ejection force measurement to determine whether the optimum amount of lubricant had been added.

- We used an adhesion punch to measure the force between the upper punch and the surface of the compact.

- We tested the formulation with different levels of lubricant at different speeds, to find the most acceptable compacts.

- We advised the client with the level of lubricant that was best for their formulation.

What Did We Discover?

We tested the formulation at low to high force to mimic the conditions of production. The formulation showed high ejection forces, this can often be managed by the addition of suitable lubricant, if too much is added this can affect the tablet strength. By assessing different levels of lubricant, we can explore the effects on tablet quality.

The sticking study was conducted at different speeds, with and without lubricant, to find a process capable of making compacts that are acceptable. We advised the client which level of lubrication was the best for their formulation and which conditions were deemed to be appropriate.

The project was completed on the hydraulic compaction simulator and was delivered under the supervision of the company, following a brief for a speedy turnaround time.

Ask Us For A Consultation Call

Or you can call us on +44(0)1384 900 265